Laser cutting and 3D both make use of laser technology

Laser, a combination of high-speed light beams, mirrors and gases that are key elements in machinery for laser cutting and 3D printing. The light beam wavelengths for these technologies are very similar though 3D printing need only heat the glue to enable its affixation and laser cutting needs a greater deal of heat to cut through materials.

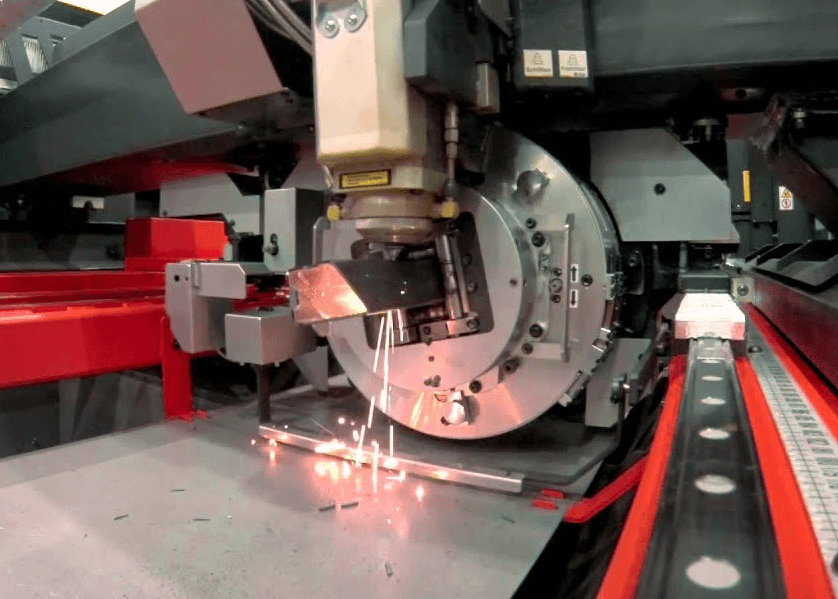

Laser cutting is a reductive process

Laser cutting reduce the size of the original material (hence a reductive process). These lasers are extremely fast and accurate allowing almost any shape to be created in little time (as compared with conventional cutting machinery). Lasers are also powerful enough to achieve similar results with ranges of materials including layers of metals inches thick and fabric, wood, and composite materials. Laser cutting works at very high speeds without losing accuracy and even with a perfect surface finish, free of burrs.

3D printing is an additive process

Whilst 3D printing also uses laser machinery to produce its products, it does so in a completely different way. Each layer is created and then added to existing layers to build a 3D, real-life version of the “printed” item. Materials used include glue, resin and similar that can easily attach to each other at certain temperatures generated by the laser.

3D printers work with less durable materials than laser cutting

3D printing has origins in prototyping and modelling rather than creating the final product. However, as the industry has grown there are many more areas of application for 3D printing. An example is in bio-suitable glues and resins that are compatible with limb movement including developments in creating prostheses!

Cost and time-consumption are significant factors in 3D printing…

Not unexpectedly cost of “inks” in 3D printing can be very high (although there are some technological developments underway to create cheaper alternatives. 3D printing can also be a time-consuming operation that commences with creation of a model for the printer and then layer, upon layer to be printed (small items of a couple of inches can take hours to produce). It may also not be possible to achieve multiple colours.

…creating opportunity for laser cutting

Laser cutting can be used to achieve a similar outcome, by changing the strategic creative thinking from additive to reductive and how to join cut pieces to create 3D. Laser cutting is significantly more flexible, working with a vast range of materials and in a fraction of time.

Hybrid between laser cutting and 3D printing

There are technology developments in 3D printing that add engraving of materials like plastic, wood, leather, carboard, paper. These laser machines work with interchangeable heads.

It is also possible to combine the various processes of 3D printing, engraving and laser cutting to achieve results in record time, with highest accuracy and technology. The age of laser is upon us with opportunity to reach heights of technology never seen before.

Nijen Stainless Fabrications

Nijen Stainless has a great deal of requests from customers in the following areas: stainless steel fabrication Northern Ireland; Laser cutting Northern Ireland; stainless steel laser cutting; stainless steel welding; CNC machining; CNC press brake; and rolling and bending.